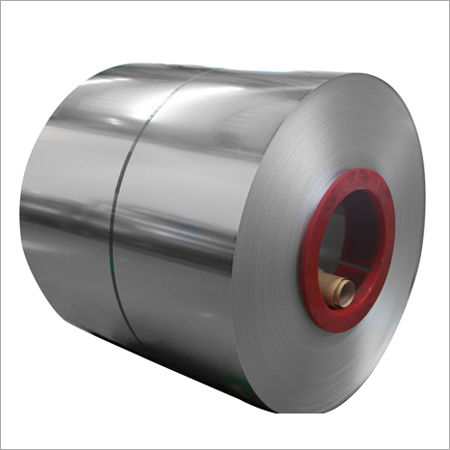

CRCA Coils

CRCA Coils Specification

- Surface Treatment

- Polished

- Material

- Mild Steel

- Technique

- Cold Rolled

- Grade

- CRCA (Cold Rolled Close Annealed)

- Coil Thickness

- 0.3 mm to 3 mm

- Coil Weight

- 1000-3000 kg per coil

- Coil Length

- As per customer requirement

- Hardness

- Soft, Half Hard, Full Hard

- Application

- Automotive, Electrical Panels, Appliances, Construction

- Tensile Strength

- 270-410 MPa

- Edge Type

- Mill Edge, Slit Edge

- Shape

- Coil

- Elongation

- 28-40%

- IS Standard

- IS 513 Grade D/E/DD

- Yield Strength

- 170-280 MPa

- Width Range

- 200 mm to 1500 mm

- Finish

- Bright, Matt

- Packing Type

- Standard Export Seaworthy Packing

CRCA Coils Trade Information

- Minimum Order Quantity

- 1500 Kilograms

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 1-7 Days

About CRCA Coils

CRCA Coils are manufactured by hot-rolled pickled steel and then annealed by heat treatment to make it thinner. These coils have high strength, unique forming properties, and high dent resistance. They are used in various industries for including automobile, electronic, machine parts making industry and various others for manufacturing of different components. Prior to dispatch, CRCA Coils are tested on stringent parameters to assure their conformance with the predefined industry guidelines. We offer them at highly competitive prices and in the wide range of specifications as requested by the customer.

Features:

-

Easy to paint

-

Good magnetic properties

-

Uniform thickness

Superior Strength & Formability

CRCA coils provide a perfect balance of tensile strength (270-410 MPa) and elongation (28-40%), ensuring excellent formability for deep drawing and fabrication tasks. Their varied hardness levels meet both flexible and rigid structural requirements, making them suitable for diverse industries.

Versatile Applications & Customization

These coils serve multiple sectors including automotive, electronics, appliances, and construction. With customizable width, thickness, and coil length, clients receive products tailored to their specifications. The mills accommodate orders with different finishes, edges, and surface treatments to suit precise needs.

Quality Assurance & Standard Packaging

Adhering to IS 513 standards, each coil undergoes strict quality checks to guarantee consistency and reliability. Our standard export seaworthy packing ensures the coils remain undamaged during transit, facilitating smooth delivery across India or internationally.

FAQs of CRCA Coils:

Q: How are CRCA coils manufactured and what sets them apart from regular steel coils?

A: CRCA (Cold Rolled Close Annealed) coils are produced by cold rolling high-quality mild steel and subsequently annealing it to achieve desired strength and ductility. This process provides a smooth, polished surface and improved mechanical properties compared to regular hot rolled steel, making them suitable for critical applications.Q: What applications are CRCA coils best suited for?

A: These coils are ideal for manufacturing automotive parts, electrical panels, consumer appliances, and used extensively in construction. Their consistent surface finish, controlled strength, and customizable dimensions make them highly adaptable to industry-specific requirements.Q: When should I choose bright or matt finish for CRCA coils?

A: Selecting between bright and matt finish depends on your products end-use. Bright finishes are preferred for visible or aesthetic components, while matt finish is suitable for painted or coated parts where glossiness is unnecessary.Q: Where do you supply or distribute CRCA coils in India?

A: We supply and distribute CRCA coils across India, serving clients as a distributor, manufacturer, service provider, supplier, and trader. Our robust logistics network ensures timely delivery in all major industrial regions.Q: What is the packing process for CRCA coils to ensure safe transportation?

A: CRCA coils are packed in standard export seaworthy packaging, which includes protective wrapping and securing measures to prevent damage from moisture, handling, and transit. This process ensures your orders arrive in optimal condition.Q: How do I determine the correct hardness and thickness of CRCA coils for my application?

A: The ideal hardness (soft, half hard, full hard) and thickness (0.3 mm to 3 mm) depend on your forming, drawing, or structural requirements. Our technical team can guide you in choosing the most suitable combination based on your application, whether for flexible shaping or structural support.Q: What benefits do I gain by using CRCA coils manufactured to IS 513 Grade D/E/DD?

A: Using IS 513 Grade D/E/DD-compliant CRCA coils guarantees consistent mechanical properties, quality assurance, and compatibility with critical applications. This standardization minimizes risk, enhances performance, and increases the longevity of your end products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

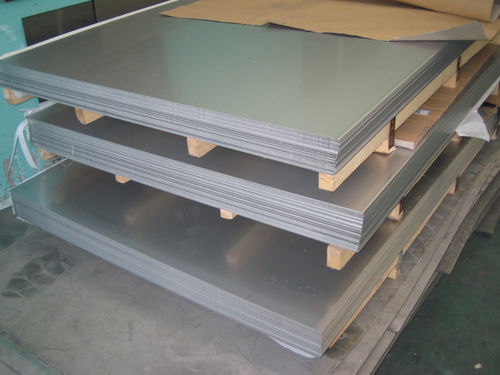

More Products in CRCA Steel Category

CRCA Sheets

Price Range 38.00 - 50.00 INR

Minimum Order Quantity : 1500 Kilograms

Hardness : Soft, Semihard, Fullhard

Technique : Cold Rolled

Grade : CR1, CR2, CR3, CR4, CR5

Coil Length : As per customer requirement

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free