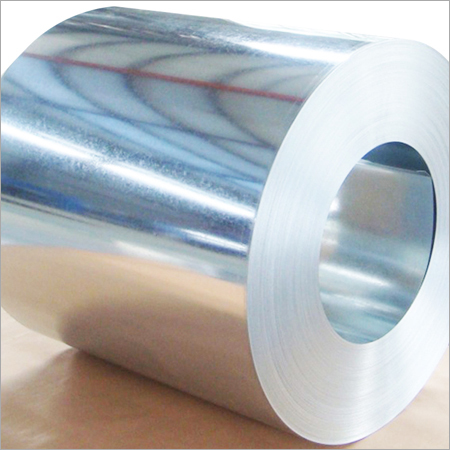

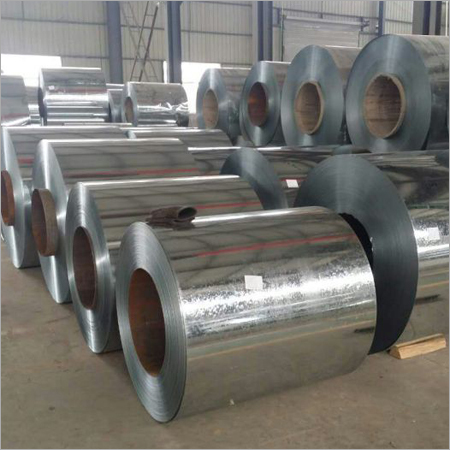

Galvanized Coils

Galvanized Coils Specification

- Surface Treatment

- Galvanized

- Material

- Steel

- Technique

- Cold Rolled, Hot Rolled

- Grade

- IS 277, ASTM A653

- Coil Thickness

- 0.14 mm to 2 mm

- Coil Weight

- 5-15 Ton

- Coil Length

- Customized

- Hardness

- Full Hard, Half Hard

- Application

- Construction, Roofing, Fencing, Automobiles

- Edge Type

- Mill Edge, Cut Edge

- Finish

- Regular Spangle, Zero Spangle

- Tensile Strength

- 270 MPa to 550 MPa

- Width Range

- 600 mm to 1500 mm

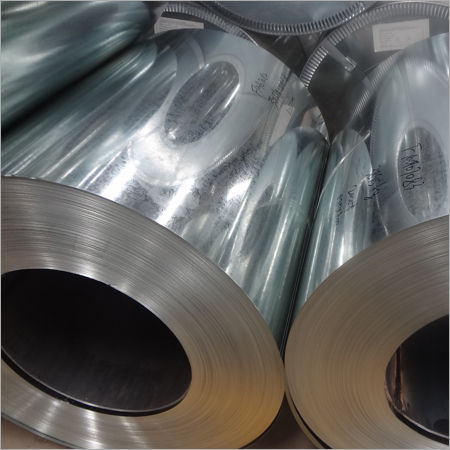

- Packing Type

- Standard Export Packing

- Zinc Coating

- 40 GSM to 275 GSM

Galvanized Coils Trade Information

- Minimum Order Quantity

- 1500 Kilograms

- Supply Ability

- 500 Kilograms Per Week

- Delivery Time

- 1-7 Days

About Galvanized Coils

Based in Mumbai, Maharashtra, we are the renowned suppliers of premium quality Galvanized Coils. These coils are made using excellent quality alloy metal and then by hot dipping them to apply a zinc coat over them. They are used in various industries for making different components and structures of variable shapes and sizes. Offered Galvanized Coils are passed on different quality and performance parameters to assure their adherence with the pre-set industry norms.

Features:

-

High class finish

-

Easy to form various structures

-

Precisely designed

Versatile Applications

Galvanized coils are extensively used in sectors like construction, roofing, fencing, and automobile manufacturing. Their robust corrosion protection and adaptability to various fabrication processes make them a preferred choice for structural and aesthetic requirements, ensuring longevity and safety in challenging environments.

Quality Assurance and Standards

Each coil adheres to rigorous standards including IS 277 and ASTM A653, guaranteeing consistent material performance. With options in hardness, edge types, and zinc coating thickness, customers receive tailored solutions matching their project specifications. Every coil undergoes thorough quality checks before packing and delivery.

FAQs of Galvanized Coils:

Q: How are galvanized coils manufactured to ensure corrosion resistance?

A: Galvanized coils are produced through either cold rolling or hot rolling processes, followed by surface treatment where steel sheets are coated with zinc. This zinc layer serves as a protective barrier, preventing corrosion and rust even in harsh environments.Q: What are the options for coil width, thickness, and zinc coating available?

A: Coil widths range from 600 mm to 1500 mm, thicknesses span 0.14 mm to 2 mm, and zinc coatings are available from 40 GSM to 275 GSM, offering versatile choices suitable for diverse project requirements.Q: When is it beneficial to select full hard or half hard galvanized coils?

A: Full hard coils are ideal for applications demanding high strength and formability, such as roofing and construction, while half hard coils offer easier bending and shaping for fencing or automotive panels.Q: Where are these galvanized coils commonly used in various industries?

A: They are used in construction for structural components, roofing sheets, fencing, and in the automobile industry for parts needing corrosion protection and durability. Their versatility extends to infrastructure and agricultural settings as well.Q: What process is involved in achieving different spangle finishes?

A: Regular spangle and zero spangle finishes are attained by controlling the solidification of the zinc coating during manufacturing. Regular spangle shows visible crystal patterns, while zero spangle provides a matte finish for specific aesthetic or functional needs.Q: How does standard export packing protect galvanized coils during transit?

A: Standard export packing ensures each coil is securely wrapped and supported to prevent damage, moisture ingress, and contamination, preserving material quality for shipment across India and international markets.Q: What are the main benefits of using galvanized coils from certified suppliers?

A: Purchasing from certified suppliers ensures you receive high-quality, standards-compliant coils that deliver reliable performance, longevity, and customization options suited to a wide range of industrial and commercial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanized Coils Category

GP Coil

Minimum Order Quantity : 100 Sheets

Hardness : Soft, SemiHard, Full Hard

Material : Other, Mild Steel

Application : Construction, Engineering, HVAC, Automobile

Technique : Cold Rolled

Surface Treatment : Galvanized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free