Galvanized Sheets

Galvanized Sheets Specification

- Surface Treatment

- Galvanized

- Material

- Mild Steel / Carbon Steel

- Technique

- Cold Rolled

- Grade

- IS 277, ASTM A653

- Coil Thickness

- 0.25 mm - 3 mm

- Coil Weight

- Standard / Custom

- Coil Length

- Customized

- Hardness

- Full Hard, Half Hard, Soft

- Application

- Construction, Roofing, HVAC, Automotive, General Fabrication

- Standard

- IS, ASTM, JIS, BS

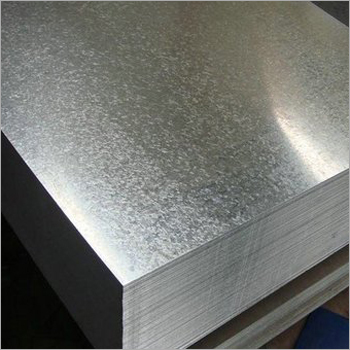

- Color

- Plain Silver

- Form

- Sheet / Coil

- Finish

- Regular / Spangle Finish

- Width

- 600 mm - 1500 mm

- Yield Strength

- 220 MPa min

- Packaging Type

- Standard Export Packaging

- Zinc Coating

- 40 GSM - 275 GSM

- Corrosion Resistance

- Excellent

- Tolerance

- +/- 0.03 mm thickness

- Edge Type

- Mill / Slit Edge

- Temperature Resistance

- Up to 315°C

Galvanized Sheets Trade Information

- Minimum Order Quantity

- 100 Sheets

- Supply Ability

- 10000 Sheets Per Day

- Delivery Time

- 10 Days

About Galvanized Sheets

Galvanized Sheets are manufactured by applying a zinc coat over the iron or steel sheets, which is achieved by a hot dipping method. These sheets are used to manufacture various mechanical products of vehicles and machinery. They are made with high efficiency by highly skilled engineers in compliance with the set quality standards. Offered Galvanized Sheets are available in different dimensional configurations and variable quantities as required according to the need of the client. Prior to dispatch, they are tested on rigorous quality parameters to assure their high class performance.

Features:

-

Rust proof

-

Robust structure

-

High class finish

Superior Corrosion and Temperature Resistance

Engineered to meet diverse industrial needs, these galvanized sheets offer excellent resistance against corrosion and operate reliably at temperatures up to 315C. The durable zinc layer, ranging from 40 to 275 GSM, ensures longevity even in demanding environments, making them particularly suited for construction and outdoor applications.

Precision Engineering and International Compliance

Our products adhere to internationally recognized standards like IS 277 and ASTM A653, ensuring precise manufacturing with thickness tolerances of +/- 0.03 mm. This commitment to quality delivers reliable performance and compatibility across global projects, further supported by our full hard, half hard, or soft hardness options.

Customized Solutions and Versatile Applications

With standard or custom coil weights and a wide range of edge types and finishes, these galvanized sheets cater to a host of requirements in construction, automotive, roofing, HVAC, and general fabrication. Available lengths are customizable, and packaging is designed for safe export, ensuring products arrive in pristine condition.

FAQs of Galvanized Sheets:

Q: How are galvanized sheets manufactured for superior corrosion resistance?

A: These galvanized sheets are cold rolled and coated with a zinc layer (40-275 GSM), which provides excellent corrosion resistance. The galvanizing process forms a protective barrier, significantly extending the sheets lifespan in various environmental conditions.Q: What industries typically use these galvanized sheets?

A: Our galvanized sheets are commonly used in construction, roofing, HVAC systems, automotive manufacturing, and general fabrication due to their strength, reliability, and corrosion resistance.Q: When should full hard, half hard, or soft varieties of galvanized sheets be selected?

A: The choice between full hard, half hard, and soft galvanized sheets depends on the applications specific forming and strength requirements. Full hard is suited for high-strength needs, while soft is preferred where flexibility and easier forming are essential.Q: Where are these galvanized sheets manufactured and supplied from?

A: We manufacture, supply, and distribute these sheets across India, adhering to IS, ASTM, JIS, and BS standards to cater to both domestic and export markets with standard export packaging.Q: What is the standard packaging and shipment process for these sheets and coils?

A: All sheets and coils are packed as per standard export packaging norms to ensure safe transit. Custom packaging options are available to meet specific customer requirements and maintain product integrity during transport.Q: How can the coil length and weight be customized according to project needs?

A: Upon request, we provide customized coil lengths and weights to suit unique project requirements. Our team works closely with clients to deliver tailored solutions for each order.Q: What are the key benefits of using these galvanized sheets in construction applications?

A: Key benefits include excellent corrosion and temperature resistance, robust mechanical strength, precise thickness tolerance, and compatibility with international quality standards. These features enhance durability, longevity, and safety in construction projects.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Galvanized Sheets Category

Galvanized Slit Coil

Minimum Order Quantity : 100 Sheets

Hardness : Full Hard / Half Hard / Soft

Technique : Cold Rolled

Grade : IS 277 / ASTM A653 / CQ / SGCC

Coil Length : Custom length as per order

Material : Other, Hot Dip Galvanized Steel

Annealed Steel Plate

Minimum Order Quantity : 100 Sheets

Hardness : Soft

Technique : Hot Rolled

Grade : ASTM, DIN, JIS

Coil Length : Customized

Material : Steel

Annealed Steel Sheet

Minimum Order Quantity : 100 Sheets

Hardness : Soft

Technique : Hot Rolled

Grade : Commercial Quality

Coil Length : Customizable

Material : Other, Mild Steel

Galvanized Iron Plate

Minimum Order Quantity : 100 Sheets

Hardness : Full Hard / Soft / Semi Hard

Technique : Other, Cold Rolled (CR)/ Hot Rolled (HR)

Grade : IS 277 / ASTM A653 / Equivalent

Coil Length : As required / Customizable

Material : Other, Galvanized Iron

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free